President Biden Celebrates Michigan’s Global Automotive Leadership At GM’s Factory Zero

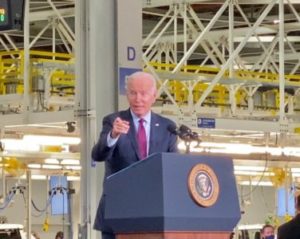

November 18, 2021 President Joe Biden came to Michigan on Wednesday, Nov. 17, to help open General Motor Co.’s retooled Factory Zero Detroit-Hamtramck Assembly Center. The President was joined by GM Chief Executive Officer Mary Barra, United Auto Workers President Ray Curry, Labor Secretary Marty Walsh, members of Michigan’s Congressional delegation, MichAuto executive director Glenn Stevens Jr., and more at the event. It is GM’s second EV plant so far within its North American footprint and is central to the company’s plan to pivot from gas and diesel-powered vehicles to EVs.

President Joe Biden came to Michigan on Wednesday, Nov. 17, to help open General Motor Co.’s retooled Factory Zero Detroit-Hamtramck Assembly Center. The President was joined by GM Chief Executive Officer Mary Barra, United Auto Workers President Ray Curry, Labor Secretary Marty Walsh, members of Michigan’s Congressional delegation, MichAuto executive director Glenn Stevens Jr., and more at the event. It is GM’s second EV plant so far within its North American footprint and is central to the company’s plan to pivot from gas and diesel-powered vehicles to EVs.

Production is now set to begin at the former Detroit-Hamtramck assembly plant, less than two years after GM announced the massive $2.2 billion investment to fully renovate the facility to build a variety of all-electric trucks and SUVs.

“GM’s U.S. manufacturing expertise is key to achieving our all-electric future,” said GM Chair and CEO Mary Barra. “This is a monumental day for the entire GM team. We retooled Factory ZERO with the best, most advanced technology in the world to build the highest quality electric vehicles for our customers.”

“GM’s U.S. manufacturing expertise is key to achieving our all-electric future,” said GM Chair and CEO Mary Barra. “This is a monumental day for the entire GM team. We retooled Factory ZERO with the best, most advanced technology in the world to build the highest quality electric vehicles for our customers.”

The name Factory ZERO reflects the significant role the facility plays in advancing GM’s vision of a world with zero crashes, zero emissions, and zero congestion. Factory ZERO will be home to the 2022 GMC HUMMER EV Pickup, 2024 GMC HUMMER EV SUV, Chevrolet Silverado EV, and the Cruise Origin, an all-electric, self-driving, shared vehicle. When fully operational, Factory ZERO will employ more than 2,200.

What it Means for Michigan

“Today’s announcement is good for Michigan, good for Michigan businesses, and another sign that Michigan’s signature automotive industry is the global leader in innovation,” said MichAuto’s Glenn Stevens Jr. “President Biden and GM’s Mary Barra highlighted the importance of the American worker and ingenuity, and MichAuto is proud to work with industry leaders to ensure our state is at the epicenter of 21st-century talent.”

While celebrating the opening of Factory Zero, President Biden promoted the passage of the Infrastructure Investment and Jobs Act (IIJA). The President celebrates industrial innovation in green technology and argued it could all be done without increasing inflation or veering into significant debt.

“We’re going to make sure that the jobs of the future end up here in Michigan, not halfway around the world,” he said. “Here in Detroit, we’re going to set a new pace for electric vehicles. This is not hyperbole. It’s a fact.”

“We’re going to make sure that the jobs of the future end up here in Michigan, not halfway around the world,” he said. “Here in Detroit, we’re going to set a new pace for electric vehicles. This is not hyperbole. It’s a fact.”

GM has committed to a future of electrification, dedicating $35 billion to electric and autonomous vehicle development and planning to launch 30 EVs globally through 2025. The automaker aims to have an all-electric light-vehicle portfolio by 2035.

IHS Markit expects battery-electric vehicle sales to make up 15 percent of U.S. light-vehicle sales by 2025 and 34 percent by 2030.

Factory ZERO – a commitment to sustainability

As an EV assembly plant, Factory ZERO plays a direct role in GM’s commitment to eliminate tailpipe emissions from new light-duty vehicles by 2035 and become carbon neutral in its global products and operations by 2040. The company has already committed to invest $35 billion in electric and autonomous vehicles and plans to introduce more than 30 EV models by 2025. Factory ZERO serves as a real-world proof point for GM’s commitment to running its business in a sustainable manner.

Factory ZERO highlights include:

- GM reused or recycled almost every material that came out of the facility during conversion, including crushed concrete from the old plant floor, which was repurposed for temporary roads around the facility.

- Storm water will be recycled to reduce discharge costs and offset the cost of potable water.

- Treated storm water will be used in cooling towers and the plant’s fire suppression system.

- The site features a 30-kilowatt solar carport and 516-kW ground-mounted photovoltaic solar array from DTE Energy.

- Factory ZERO’s site has a 16.5-acre wildlife habitat that is home to monarchs, foxes and turkeys.

Through Factory ZERO, GM is showcasing its manufacturing leadership capability and readiness for what will be a fundamental shift in mobility as the company transitions to an all-electric future.